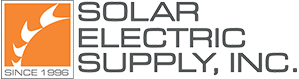

Cost-Effective All-Terrain Mounting

The IronRidge Ground Mount System combines engineered XR100® or XR1000® aluminum rails with locally-sourced steel pipes or mechanical tubing to create a robust, cost-effective structure capable of handling any site or terrain challenge. This system works seamlessly across both residential and commercial applications.

Installation is simplified with only a few structural components and no drilling, welding, or heavy machinery required. The system supports multiple foundation options including concrete piers, ground screws, helical piles, driven piles, and above-ground ballast blocks, making it compatible with soil classes 2-4 and various site conditions.

Rugged Construction

Engineered steel and aluminum components manufactured from 6000-series aluminum alloy ensure long-term durability and structural integrity.

UL 2703 Listed

Complete system and components meet the newest effective UL 2703 standard for photovoltaic mounting systems.

PE Certified

Pre-stamped engineering letters available in most states, simplifying permitting and approval processes.

Flexible Architecture

Multiple foundation and array configuration options accommodate various site conditions and installation requirements.

Simple Installation

Only a few structural components required with no drilling, welding, or heavy machinery needed for installation.

25-Year Warranty

Products guaranteed to be free of impairing defects with comprehensive manufacturer warranty coverage.

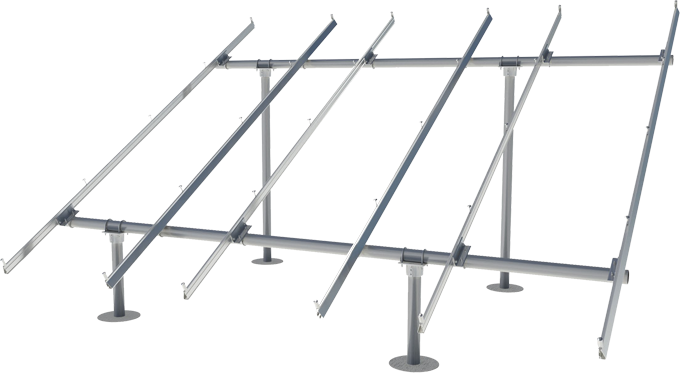

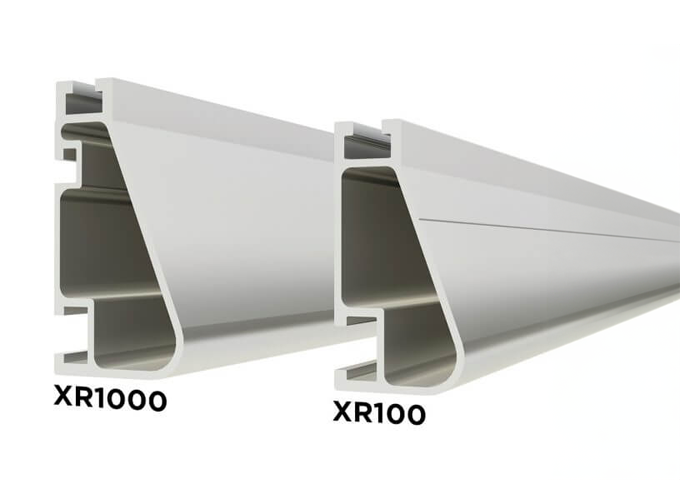

Aluminum Rail Systems Engineered for Strength

XR Rails feature a unique curved profile that increases structural strength and spanning capability, meaning fewer roof penetrations and more cost-effective designs for both residential and commercial applications. Available in Mill finish aluminum, or black anodized aluminum. Clear Anodized is available as a special order.

XR100® Rail

This ironridge mounting rail support a range of wind and snow conditions while maximizing spans up to 8 feet. Perfect for both residential and commercial installations requiring heavy load capability.

XR1000® Rail

A heavyweight among solar mounting rails, built to handle extreme climates and spans up to 12 feet. Engineered for both residential and commercial applications requiring maximum structural performance.

XR Rail Configurations & Part Numbers

| XR Rail | Model # | Length | Finish | Description |

|---|---|---|---|---|

| Ironridge XR100® | ||||

| XR100® | XR-100-168M | 168" (14 ft) | Mill | XR100, Rail 168", Mill |

| XR100® | XR-100-168B | 168" (14 ft) | Black | XR100, Rail 168", Black |

| XR100® | XR-100-184M | 184" (15.3 ft) | Mill | XR100, Rail 184", Mill |

| XR100® | XR-100-184B | 184" (15.3 ft) | Black | XR100, Rail 184", Black |

| XR100® | XR-100-204M | 204" (17 ft) | Mill | XR100, Rail 204", Mill |

| XR100® | XR-100-204B | 204" (17 ft) | Black | XR100, Rail 204", Black |

| Ironridge XR1000® | ||||

| XR1000® | XR-1000-170M | 170" (14.2 ft) | Mill | XR1000, Rail 170", Mill |

| XR1000® | XR-1000-210M | 210" (17.5 ft) | Mill | XR1000, Rail 210", Mill |

IronRidge Ground Mount System Components

Substructure

Top Caps

Anchor, flash, and mount with all-in-one attachments.

- Ships with all hardware

- IBC & IRC compliant

- Certified with XR Rails

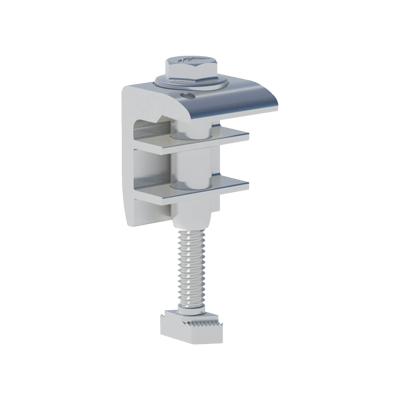

Bonded Rail Connectors

Drop-in design for rapid rail attachment.

- High-friction serrated face

- Heavy-duty profile shape

- Clear & black anodized finish

Diagonal Cross Braces

Raise flush or tilted systems to various heights.

- Works with vent flashing

- Ships pre-assembled

- Lengths from 3” to 9”

Cross Pipe & Piers

2” or 3” Schedule 40 Grade B pipe & mechanical tubing.

- Locally-sourced pipe

- spans up to 18’ between piers

- helps save on freight costs

Rail Assembly

XR Rail® Family

Slide in clamps and secure modules at ends of rails.

- Mill finish & black anod.

- Sizes from 1.22” to 2.3”

- Optional Under Clamps

EFO™

The End Fastening Object you need to get the job done

- Fits module heights of 30-40mm

- Available in Mill or Black Finish

- Fully certified, 25-year warranty

Boss® Bonded Splice

Provides a strong, bonded connection for XR Rails®

- No assembly, tools, or hardware.

- built-in bonding spring w/ Teeth

- Can be used for short rail extensions beyond Top Cap

CAMOTM

Bond modules to rails while staying completely hidden.

- tool-free, universal, invisible end clamp

- comes as one piece, fully assembled

- improves array aesthetics

Multiple Foundation Options for Any Site Condition

The IronRidge Ground Mount System supports various foundation methods to accommodate different soil conditions, site requirements, and project specifications. Choose the optimal foundation type for your installation.

Standard Foundation Methods

Concrete Piers

Poured concrete piers provide excellent resistance to vertical and lateral loads, constructed with readily available materials.

Key Benefits:

- Excellent load resistance

- Readily available materials

- Standardized design options

- Backed by stamped engineering letters

Ground Screws

Ground screws are gaining popularity for their versatility, quick installation, and low impact on land drainage.

Key Benefits:

- Quick installation process

- Low impact on land drainage

- Compatible with Krinner G-Series

- Certified systems engineering letter available

Alternative Foundation Methods

For specialized site conditions or project requirements, the Ground Mount System can be installed using alternative foundation methods. Each method requires professional engineering analysis.

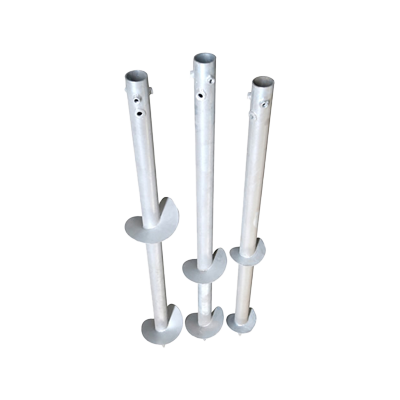

Helical Piles

Provide very good resistance to uplift forces but minimal lateral load resistance compared to standard concrete foundations.

Engineering Considerations:

- Requires Professional Engineer (PE) analysis

- Shorter E-W pier spans required

- More piers needed for stability

- Additional bracing may be required

Driven Piers

Pile-driven or vibratory-driven piers require specialized equipment and analysis of soil bearing capacity and corrosivity.

Project Requirements:

- Geotechnical Engineer soil analysis

- Specialized installation equipment

- Deeper foundations required

- Custom PE foundation design letter

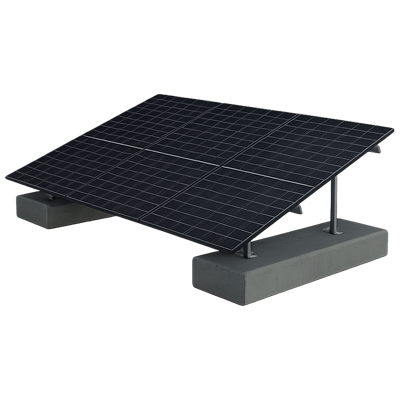

Ballasted Systems

Common for brownfield sites like landfills where cap layers cannot be penetrated. Can be cast-in-place or pre-cast concrete blocks.

Application Benefits:

- Ideal for brownfield/landfill sites

- No ground penetration required

- Cast-in-place or pre-cast options

- PE determines block sizing requirements

IronRidge XR Documentation

Different solar panels, PV mounts, storage, & inverter systems available at low wholesale prices

Contact Us Today for sales, quantity discounts and expert reviews for the IronRidge Ground Mount System.

Residential Ground Mounted Systems

We have the best residential solar system solution for your ground mount solar project at a low wholesale price.

Learn MoreContractor Discounts Available

Join our network of authorized contractors for special discount pricing on our complete solar panel system kits.

Learn MoreResidential Solar Carport Systems

Check out our selection of top quality Solar Pergolas, Pavilions, & solar carports, endless customization options!

Learn More